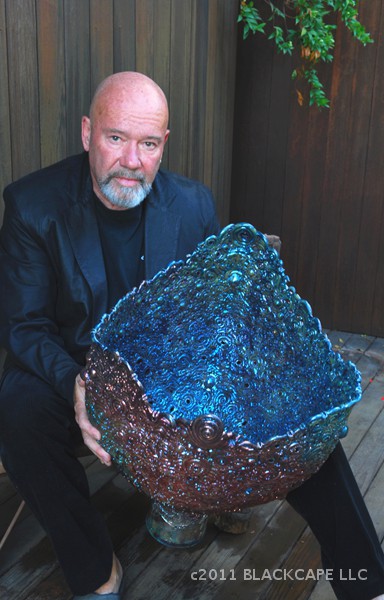

Potters and Sculptors

Human culture has been dominated by pottery and ceramics for thousands of years. Innumerable human endeavors have relied on pottery and ceramics, from prehistoric storage jars to tiles on the space shuttles. Ceramics are materials that are permanently altered when heated. When dried clay objects are put in water, they will slake down (disintegrate) due … Read more